What, in your view, defines design? What constitutes good or innovative design?

What, in your view, defines design? What constitutes good or innovative design?

Dyson: For me, design is about how something works, not about what it looks like. It's what's inside that counts. Good design solves problems and changes something for the better. Aesthetics should be a by-product of the design, not the other way around.

My patented Cyclone Technology, which makes the Dyson brand different from and better than other vacuum cleaners, lies at the core of our machines. We design the rest of the vacuum around this core technology. We are increasingly designing with a specific market in mind. In Japan, for example, we created a compact vacuum with a cleaner head customised specifically for Japanese tatami mats. In the US, we have just launched a robust heavy-duty cleaner nicknamed the Work Horse, having engineered this machine especially for Americans who have thick shag-pile carpets.

What philosophy do you follow regarding design; what aspects must the designer incorporate?

Dyson: The look of our vacuum cleaners derives solely from their function and ease of use. Appearance alone does not make a good product. I am happy when someone does not like the colour of a Dyson vacuum cleaner because it proves the person bought it because of its performance, not its looks.

If you buy a wonderful-looking electric kettle that burns your fingers — never again will "beauty in the eye of the beholder" seduce you. A product's only true beauty lies in its working properly. People won't buy a design that merely looks good twice.

I am not immune to beautifully designed objects, but I feel that you quickly come to hate a styled design that is not up to the job, but fall in love with an unstyled product that works well.

As a prolific inventor of popular items that have generated lots of sales, could you share with us where the inspiration and innovation that become mega hits came from? Do you know of any structured ways or guidelines that aid the process?

Dyson: My inspiration has always been frustration. Logically, if a problem exists, then a solution must too. Frustration led me to design the Ballbarrow (a new take on the wheel barrow — minus the wheel) and later the Dual Cyclone vacuum cleaner.

The idea for the first Dual Cyclone vacuum cleaner arose from my bemusement and annoyance at finding that the bag in my top-of-the-line Hoover vacuum cleaner had clogged and the suction failed after vacuuming just one room of my house. I took it apart to see the cause of the problem and found that dust had lined the bag, thereby clogging the pores and reducing intake. I decided to make something better.

The fundamental design for the vacuum cleaner had not altered for almost a century. I took five years and 5,127 prototypes to perfect my design. This Edisonian approach to design is one I always encourage Dyson engineers to adopt. It comprises tiny step-by-step changes. Rather than spend ages planning and sketching, I just kept building prototype after prototype until I got it right. I am now a big believer in the importance of making mistakes; they help you learn and can often lead you into uncharted waters and in exciting new directions.

What key lesson did you learn from the process of developing the Cyclone? Would you have done anything differently?

Dyson: If you can, do it yourself. I wish that I had had the conviction to go out on my own right from the start. I spent too much time trying to find a backer or seeking a licensing deal with a large manufacturer.

I also advise people struggling to make their designs a reality to persevere. They will need doggedness to push through the moments of frustration to make ideas into reality.

If you believe in your idea, stand by it and don't let anyone or anything sway you. If you can make something better, go ahead and be different. Don't give up if people reject your ideas. Try to trust your instincts. I think many people give up just as they are about to succeed.

I wanted a clear bin on my vacuum cleaner because I believed people would want to see how their machine performed, that is, how much dirt it picked up. Some people thought I was mad, and one retailer even requested that I frost the bin before they sold it. A few months later though they acquiesced, admitting that people actually asked for the Dyson with a clear bin.

How many patents do you hold and do you encourage inventors to file their discovery for protection?

Dyson: To stay ahead, Dyson files one new patent every day. The total number so far comes to about 1,300 and is growing.

If you have done something new and have developed a better product, you can acquire intellectual property rights. A patent stops people from copying your work and allows you to take action to prevent their doing so. When Hoover copied our technology, we took them to court because we had a patent for our design.

Patents are expensive to file, however, and you need to apply in each country where you want protection. Then you have to renew annually in every country — it costs £2,000 a year for Germany alone. I have taken this matter to the European Court of Human Rights — why should inventors lose their rights just because they cannot afford annual renewal fees that effectively tax innovation? The court has rejected my case twice. Big companies can file any patent they want to anywhere in the world, but individual inventors or small businesses cannot afford it. Moreover, any court action to fight plagiarism also costs a great deal. Patents are expensive to file, however, and you need to apply in each country where you want protection. Then you have to renew annually in every country — it costs £2,000 a year for Germany alone. I have taken this matter to the European Court of Human Rights — why should inventors lose their rights just because they cannot afford annual renewal fees that effectively tax innovation? The court has rejected my case twice. Big companies can file any patent they want to anywhere in the world, but individual inventors or small businesses cannot afford it. Moreover, any court action to fight plagiarism also costs a great deal.

What do you think about designing for the masses as opposed to designing for niche or specialised customers?

Dyson: I believe in making products that work better than those that already exist no gimmicks; just innovative design and technology. I think that all people want this, irrespective of their income or interests. We design our machines for anyone and everyone with dirt in their homes. Good design is not elitist.

With globalisation blurring boundaries, how do you make your design stand out or reflect your identity? How can Asian — particularly Singaporean — designers maintain their cultural and geographical uniqueness when facing this challenge?

Dyson: It is imperative to stay true to your values. Although Dyson as a company has obviously grown, our attitude and spirit remains the same as it was some 14 years ago — and that's in every market, not just in the UK. Of course, we have an advantage because Dyson works to improve everyday technology; we always look ahead so we never get complacent.

Since 1993 we have radically changed our vacuum cleaner design and introduced new products such as the Contrarotator washing machine, the Dyson Airblade hand dryer, and Dyson Root 6 — our first handheld vacuum cleaner. We also developed the Dyson Digital Motor used both in the vacuum cleaner designed specifically for Japan and in the Dyson Airblade.

We maintain our identity by concentrating on better technology and superior products. We invest wholeheartedly in research, design, and development — our lifeblood.

What design trends do you observe and what challenges lie ahead for designers? How can they prepare for or address them

Dyson: A real trend that has now sprung up in technology is miniaturisation. Palpable competition exists among companies to make their products and components as small as possible, with Apple having released the smallest MP3 player in the world in 2005.

Nanotechnology will open up many exciting possibilities for innovations; however, it will also bring with it a myriad of challenges. When designing a vacuum cleaner for Japan, we concentrated levels of performance. motor because compartment. nine years and to come.

How can the public, educational institutions, government, and industry contribute to building up design and embracing it?

Dyson: It is vital that we encourage the next generation to see design as exciting, dynamic, and fundamental to the world in which we live. Such an emphasis today rests on academic achievement, which however important should not overshadow creativity through design.

Design, technology, and art constitute costly subjects for schools. As a result, fewer young people get exposure to creativity and design and think it dull and geeky — more about fixing things. We need to overcome this negative perception and show them how exciting creative design can be. Design, technology, and art constitute costly subjects for schools. As a result, fewer young people get exposure to creativity and design and think it dull and geeky — more about fixing things. We need to overcome this negative perception and show them how exciting creative design can be.

Consequently the James Dyson Foundation has announced plans for the Dyson School of Design Innovation in Bath, the first of its kind in the UK. It will give young people the freedom to explore and experiment with ideas in a dynamic and exciting environment. Students will get to meet and work with design engineers from Dyson, Airbus, Rolls-Royce, and other engineering firms.

The foundation will also provide free relevant resources for design and technology teachers, as well as support for creative projects that give children the chance to take part in the design process. We encourage a fun, hands-on approach to design technology. Dyson engineers also run workshops with children around the UK and overseas, encouraging them to think differently about everyday products.

From the end of February to early March 2007, Dyson engineers conducted workshops and presentations on design engineering in Singapore and Malaysia, visiting tertiary institutions such as the National University of Singapore, the Temasek School of Design, and the University Technology in Malaysia.

What designs of the 20th century do you consider the most innovative? Which ones do you think have had the greatest impact?

Dyson: It is difficult to choose one as so many have emerged. However, I would like to highlight a few of my favourites. The JCB digger — before 1953, no one had ever dug a ditch without a hand shovel. Joe Cyril Bamford's JCB digger, the first to use hydraulic power, transformed construction and agricultural equipment in Britain and the rest of the world.

The Austin Morris Mini — Alex Issigonis decided in the late 1950s, following the success of the Morris Minor, that Britain needed an even smaller family car. It was less than ten feet long, yet could easily carry four people. It seduced us all and still does 50 years later. With over 6 million sold, it has never gone out of fashion.

Finally, the Concorde — though out of commission now, the BAC/Sud Concorde was revolutionary in many ways. It carried commercial passengers at speeds much faster than that of sound. Its beautiful double-delta wing formation with no need for a tail soon became a familiar and enchanting sight in British skies.

The Dyson Design Process

The Dyson Design Process

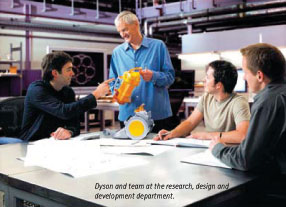

Design at Dyson focuses on challenging the norm, developing new technologies, and making things work better. The 420-strong Research, Design and Development (RDD) department based in Wiltshire, UK works on areas as diverse as fluid, mechanical, electrical, thermal, acoustic, and software engineering, supported by a microbiology laboratory.

Dyson engineers practise an integrated approach to design where they view designing, engineering, model-making, testing, and machining as overlapping disciplines without boundaries.

- Engineers start by questioning existing technology and brainstorming aspects that can be improved to challenge the norm. This forms the basis of their design specification.

- Initial ideas are then sketched; sketching may seem crude but it enables engineers to develop creative ideas and details quickly, freely, and realistically.

- Cardboard modelling rapidly establishes the fundamental layout of the product. As the design progresses, designers use cardboard to accurately model each individual part, allowing design details to be resolved prior to the much slower phase of Computer Aided Design (CAD) modelling.

- Next comes a series of breadboard models — these rough working prototypes test ideas and measure performance. They consist of a mixture of materials: parts of current Dyson products, plastic, metal, and some CAD prototyped components. Breadboard models are ready to undergo basic tests including — in the case of vacuum cleaners — pick-up, performance, and sound testing. They are cheap to make, malleable and are vital for solving key issues during early stages.

- Engineers can study the airflow through the machine (fluid dynamics) and the load-bearing strength of the design (finite element analysis) from CAD files on the computer.

- Dyson uses a Rapid Prototyping system known as Selective Laser Sintering (SLS) and other techniques to make 3D prototypes. A manager with rapid prototyping expertise advises on the most appropriate method.

- The SLS prototyping system works by laying down a very thin layer of plastic powder, which upon heating by a laser, melts and reforms as solid plastic. The process repeats layer by layer until a plastic part forms.

- Foam modelling rounds up the final stages of the design process for visual and ergonomic fine-tuning.

- Engineering Build 1 machines can be put through final mechanical, acoustic, and pick-up tests. Dyson employees bring them back to test in their own homes.

- General Assembly drawings indicate how all the components of a finished product fit together.

|

Click here to download the full issue for USD 6.50 Click here to download the full issue for USD 6.50

|

What, in your view, defines design? What constitutes good or innovative design?

What, in your view, defines design? What constitutes good or innovative design?

Patents are expensive to file, however, and you need to apply in each country where you want protection. Then you have to renew annually in every country — it costs £2,000 a year for Germany alone. I have taken this matter to the European Court of Human Rights — why should inventors lose their rights just because they cannot afford annual renewal fees that effectively tax innovation? The court has rejected my case twice. Big companies can file any patent they want to anywhere in the world, but individual inventors or small businesses cannot afford it. Moreover, any court action to fight plagiarism also costs a great deal.

Patents are expensive to file, however, and you need to apply in each country where you want protection. Then you have to renew annually in every country — it costs £2,000 a year for Germany alone. I have taken this matter to the European Court of Human Rights — why should inventors lose their rights just because they cannot afford annual renewal fees that effectively tax innovation? The court has rejected my case twice. Big companies can file any patent they want to anywhere in the world, but individual inventors or small businesses cannot afford it. Moreover, any court action to fight plagiarism also costs a great deal.

Design, technology, and art constitute costly subjects for schools. As a result, fewer young people get exposure to creativity and design and think it dull and geeky — more about fixing things. We need to overcome this negative perception and show them how exciting creative design can be.

Design, technology, and art constitute costly subjects for schools. As a result, fewer young people get exposure to creativity and design and think it dull and geeky — more about fixing things. We need to overcome this negative perception and show them how exciting creative design can be.

The Dyson Design Process

The Dyson Design Process

Click here to download the full issue for USD 6.50

Click here to download the full issue for USD 6.50